Комментарии:

Love the videos Bob! People with no rhythm, coordination and steady hands like me have a real appreciation for folks with skills like you!

Ответить

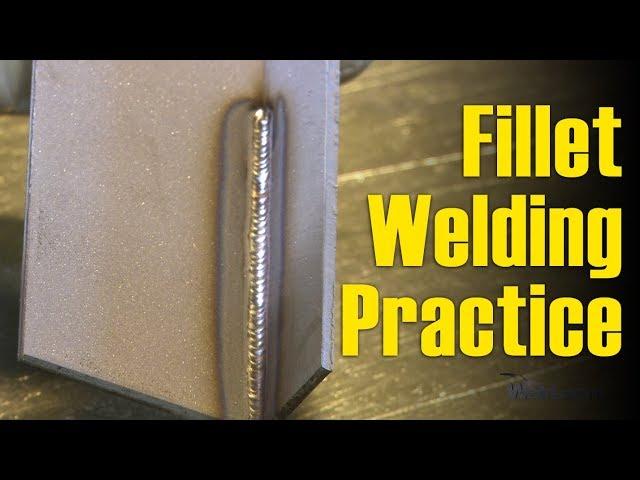

im doing the same weld in class and im cooking that backside just like you showed. your aperage was at 125. is the trick to not destrying that side speed ? i really enjoy your videos and personality

Ответить

ha ha ha!!!! Yeah it is always good to have a ground!!!! Been there done that so many times when repositioning large parts. Great video! Thank you Bob.

Ответить

Do you not have a welding vac ? doesn't seem very safe to me that you not have a vac for all of those fumes .. .

Ответить

Lol if nothing else bob you're entertaining.

Ответить

Good video Bobby,

Ответить

really helpful and instructive videos. really like the expressive tone

Ответить

Can you drag your cup on the material you are welding on to keep my hand more steady?

Ответить

aWesome Bob thanks for the good ole' 'basic' inspiration.. im heading out to the garage now to run some beads and build up some 'hands on' experience.. the thing that cant be bought :D WeldON!

Ответить

would this have been welded with a 60 degree tungsten grind?

Ответить

Don't have to wiggle the cup?

Ответить

teaching this old stick welder guy a a new trick thanks bob

Ответить

Thanks Bob for all the info on Everlast 200DV welder and showing practice welds. I purchased that exact welder. Ive taught myself to weld with your videos. Just have to master the tee joint or 2F if thats the correct name

Ответить

What size filler rod was used, i am trying to use 1/8 inch er70s-6 at on an 1/8th inch material fillet weld like in the video but i think my filler rod is just too big, would 1/16 be a better choice?

Ответить

how thick are the metals? he said 8 inch thin material? That is not 8 inches thick, to me it looks like 3mm, am i right? considering the high amounts of amps hes using...

Ответить

Bob I've been stick and mig welding for 50 years recently I purchased a mig tig stick machine and thought I would try tig welding Bob I suck at it I will try some more running straight beads but its bad I can't imagine tig overhead I would set myself on fire I can weld 7018 vertical up and the slang jumps off no good at tig but I'll keep trying like you say flat straight welds thanks for showing.

Ответить

hahaha dont feel bad i try to weld without a ground all the time haha

Ответить

Nothing more frustrating than forgetting ground clamp. I feel your pain. Lol

Thanks for the great videos

To feed the filler wire is such a tough job......and i fail to do that. It is the most difficult welding, i mean TIG

Ответить

Love the no BS attitude Bob. Do it once and do it right.

Ответить

I follow everything this man says like gospel

Ответить

Маска правильная у него.

Ответить

In school right now for TIG. our teacher has us doing this today on 65 amp and no one could do it. Took 3 hours to make 1 half ass fillet. Keep burning thru and getting no filling. Having a hard time keeping the right angle and when to add filler rod. Teacher basically just shows us what he does and no more constructive criticism. At my wits end.

Ответить

how can i weld the sch 40 tube stainless what parameter needed sir?

Ответить

Bob, Wonderful welding but I think you missed you calling as a voice artist. What a great voice.

Ответить

REPETITION is the MOTHER of LEARNING. - Latin proverb (Repetitio est mater studiorum.)

Ответить

Thank you so much Bob, for reaffirming that we don’t need a ton of weld to hold things effectively. Great video for us newbies. I learned a lot just by watching this video.

Ответить

Don’t know where Bob is these days, but I am thankful that he did these great videos. Bob, if you’re still with us, would love to see you post on FB.

Ответить

thank you!

Ответить

For the first minute of this video, I can not believe anyone would say the things that you said that you've heard. How negative, and that's the sort of indivudual that gets nowhere in life. I am all ears, Bob. I just wish i had a house that i didn't rent so i could practice TIG at home. I can't run the amps anywhere here.

Ответить

I'm trying to TIG weld a fillet and the vertical piece burns right out before I get a puddle on the bottom - both pieces are 16ga...I'm new to TIG - I don't have this problem when I'm welding with my Ac/Oxy torch...where do I start?

Ответить

So good I watched it twice, so far! Thank you!

Ответить

Does a filler wire rod have a correct end? I didn’t know that!

Ответить

Why do I have a green flame 🔥? I’m using pure argon.

Ответить

Your bad weld looks like my best tig weld!

Ответить

How do you get to Carnegie Hall? Practice! Thank you for making a very well produced video.

Ответить

Bob, love you videos, demeanor and most importantly, the information you share. Thanks!

Ответить

Koopins lmfao

Ответить

Brilliant. I love your videos. I'm 61 years young and I'm at college learning TIG welding in the UK. I work for an aerospace company as a skilled fitter and we CANNOT get TIG welders. So I thought lets go for it and learn myself. I love it, wish I'd started years ago.

Ответить

Good to go

Ответить

I am yelmuniym tig and co2 mig and ms, ss tig weldar you visha gibh i am puar man

Ответить

Answered lots of my questions , one of the exercises we have to do at college. I keep getting the scorched end. So this has helped out lots , especially practicing at home. Thanks.

Ответить

Not much I enjoy more than sitting down and learning from an old timer who's been welding/working with steel his whole life. Every little trick I've learned as a MIG/stick welder has come from an old timer who saw I was open to taking advice and took me under their wing.

At my first welding job, in 2 years I went from knowing just enough to get horizontal flat mig/stick certs, to doing production welding, to doing layout and fitting for handrails, to also running the shop. I blew past guys who had been there doing just welding of work fitted by other guys because I didn't get upset or argue when someone more experienced gave constructive criticism and I spent my free time asking questions and developing my skills

I think the two things that allowed me to move up so quickly were:

1. I assume everyone you meet has something you can learn from them (never assume you're above taking advice from someone - don't let your ego hold you back) and

2. be proactive - If I saw something I could fix or improve, even if it was far outside my job description, I would just do it and tell my boss after it was done. (an example would be teaching myself to operate the forklifts on my lunch break when I first started - no one had time to train me and not knowing how to safely move around raw materials (shortest stuff we'd get was at least 10', most stuff was 20', so it wasn't like moving a pallet..).

Find things you can do that show the company you have more skills to offer than what they initially hired you for - they only knew I could setup, repair and troubleshoot anything with an engine because I proved it through fixing a forklift, a few welding machines, a crane... Once they saw that I had other skills beyond apprentice-level welding they started adding responsibilities and, although my welding was beginner quality, I was basically operating as the foreman of the shop after a little over 1 year in the industry

I got 3 pay raises in only 2 years at that company and by the time I left I was running the place (there were 3 fitters, a helper and me.. I started in the same position as the helper who had been there 10+years) - when I started there I had only been welding for 2 months

Amazing Bob once again spreading wisdom!

Ответить

+1 For Mr. Bob Moffatt

Ответить

This is extremely helpful. I was making washed out welds that were too large and my instructor told me it was because I was using too much amperage. This video taught me that my issue was that I had too long of an arc length. Seems obvious now, but it was "light bulb" moment for me.

Ответить

![MY REACTION THAT I GOT A WIX AD THAT USES THE [BC SFX] FOR THE 14TH TIME!!!!!!!!!!!!!!!!!! MY REACTION THAT I GOT A WIX AD THAT USES THE [BC SFX] FOR THE 14TH TIME!!!!!!!!!!!!!!!!!!](https://smotrel.cc/img/upload/TWN5dm9fclZWMFg.jpg)