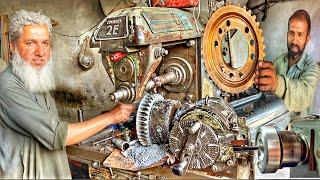

70 Year old man made the part which is not available in the market , did a great job

Комментарии:

I have seen a lot of engineers struggle to work out how to use a dividing head and this guy uses a piece of chalk

Ответить

Outstanding workmanship.

Ответить

Excellent job ! 👍

Ответить

Las coronas se hacen en bronce fosfórico.. no en aluminio

Ответить

That gear is brass.....for a reason. It wears preferential over the hardened worm gear. Making it out of steel is going to destroy the gearset.

Ответить

Very good 🇧🇷🇧🇷🇧🇷🇧🇷🇧🇷🇧🇷

Ответить

It's a pity he didn't make it out of bronze. Despite the excellent workmanship I can't see this one lasting too long.

Ответить

For a man of 72 in a sweatshop environment in Pakistan or the like on a 60s 70s or 80s machine with no CAD help turning a block of Ali into a functioning machine part is beyond remarkable,

Ответить

How did he achieve precision ? Amazing skills.

Ответить

Garbage grade aluminum gears? Useless- I think this is a joke Wear out in 5 minutes

Ответить

Aluminium way to soft need phosfor bronze

Ответить

Even if you don’t have the machinery to make it the easiest way the skills that the old man has learned served him well and the part worked

Ответить

Worm wheel,not worm gear.

Ответить

How did the old British Adcock shipley miller end up in Pakistan.

Ответить

He is a very skilled machinist, but he should have some eye protection from splinters and swarf. His beard was dangerously close to getting caught in that milling arbour!

Ответить

I like that the machinist keeps his machines relatively clean and uses that rarest of commodities, oil, during machining operations. I don’t doubt it’s expensive, but even used engine oil will be much better than nothing, or water, seen in many rural workshops.

Ответить

I remember in my apprenticeship days (1963) using this machine technology. Great skill is required. I doubt the young fella doesn't even know what a manual dividing head is. These guys are great artisans in my book.

Ответить

Another old grease monkey here. Still treading the duck boards. I like this engineering, this flying by the seat of your pants engineering. I am happy to see all health and safety crap out of the way. These machines kill and these guys have learnt to keep out of harms way. They get the job done. Respect.

Ответить

It may not be on the market where your at, but it is here, I changed a lot of those gears / circle drive gear for motor graders that use it.

Ответить

Great skill but I'm confused. He had a bronze wheel to start with so why make another in aluminium alloy, which is entirely unsuitable as a substitute? The friction loadings from the steel worm would destroy the replacement in minutes.

Ответить

I like how it's always an old man. As if that going to get you more views.

Ответить

Where can I get the Health and Safety Sandals please ??

Ответить

Ein Schneckenrad aus Aluminium? Wie lange soll das halten? Die Fertigungstechnik jedoch ist beeindruckend.🙄🙄🙄🙄 Viele Grüsse aus Germany

Ответить

Loads of comments saying how good this work is. They have used ally of some sort! That's useless for a worm gear if that size. The original was of bronze type, fir a reason

Ответить

I have watched several of these…they are unbelievable

Ответить

I don't understand what the point is? That a 70 year man can operate a few machines? I bet there are thousands of people over 70 that can do this.

Ответить

ممكن العنوان

Ответить

OMG A screwdriver to hold the lathe in place. SMH.

Ответить

Ah yes the handy dandy all purpose vernier calipers.

Ответить

Doesn’t look over 70. 40-45

Ответить

No mill skta hay en ka

Ответить

Stupid Video. The age of a craftsman does not necessarily reflect the competence

Ответить

Would have liked to see them drilling the holes and seeing the finish product ???

Ответить

india #1 world super power

Ответить

I just thought of something. Probably by next year they will invent an AI driven Bridgeport machine and no machinists will ever be needed again.

Ответить

Aluminium is the wrong material

Phosphor Bronze or Brass these are always made from

Súper. No se varan y, hacen que una máquina o equipo de gran valor no se detenga y dañe. Mucho ingenio y Dios los siga bendiciendo.

Ответить

Super work❤

Ответить

.... Never Personal Protective Equipment, PPE used ......

Ответить

These craftsmen make the best use of available tools and what they have learnt.

Ответить

Adcock and Shipley of Leicester, UK Machine still going. It looked like the original gear was bronze, I assume the aluminium copy was for lighter duty.

Ответить

Sois unos genios, ya no quedan personas que sepan hacer estas cosas.

Ответить

My dad was the Master Machinst for TWA in KCMO for 35 years. He worked on B52s in the Air Force also.

Ответить

And to think all these machines were made in the UK and then when the factories closed down they were shipped to India and Pakistan and still work to this day,,great workmanship

Ответить

That dude doesn’t look 70.

Ответить

chinese wrench.

Ответить

old British busses had some sort of bronze gears in back axle and lasted for decades.

my foreman once bought and old bus and when he dismantled the back axle was amazed at the big bronze gears.

I always like the health and safety shoes 👞😃😃😃

Ответить

Greetings from Finland. These men are real professionals and this video is educational for those youngsters who want become machinists. Here you see the whole process and the way how to measure and compare the items.

This reminds me about the times I was working in a metal workshop for three months which was needed when I was in the Technical College of Helsinki some 50 years ago. I was in radio and TV line but those 3 months were very educational. I learned many processes like lathing which really was my favorite job. Even if I didn’t need much of these in my day job in a large TV company, I needed the practises in my all kind of hobbies. 😁

Why the voice has mond0k style??🙉

Ответить